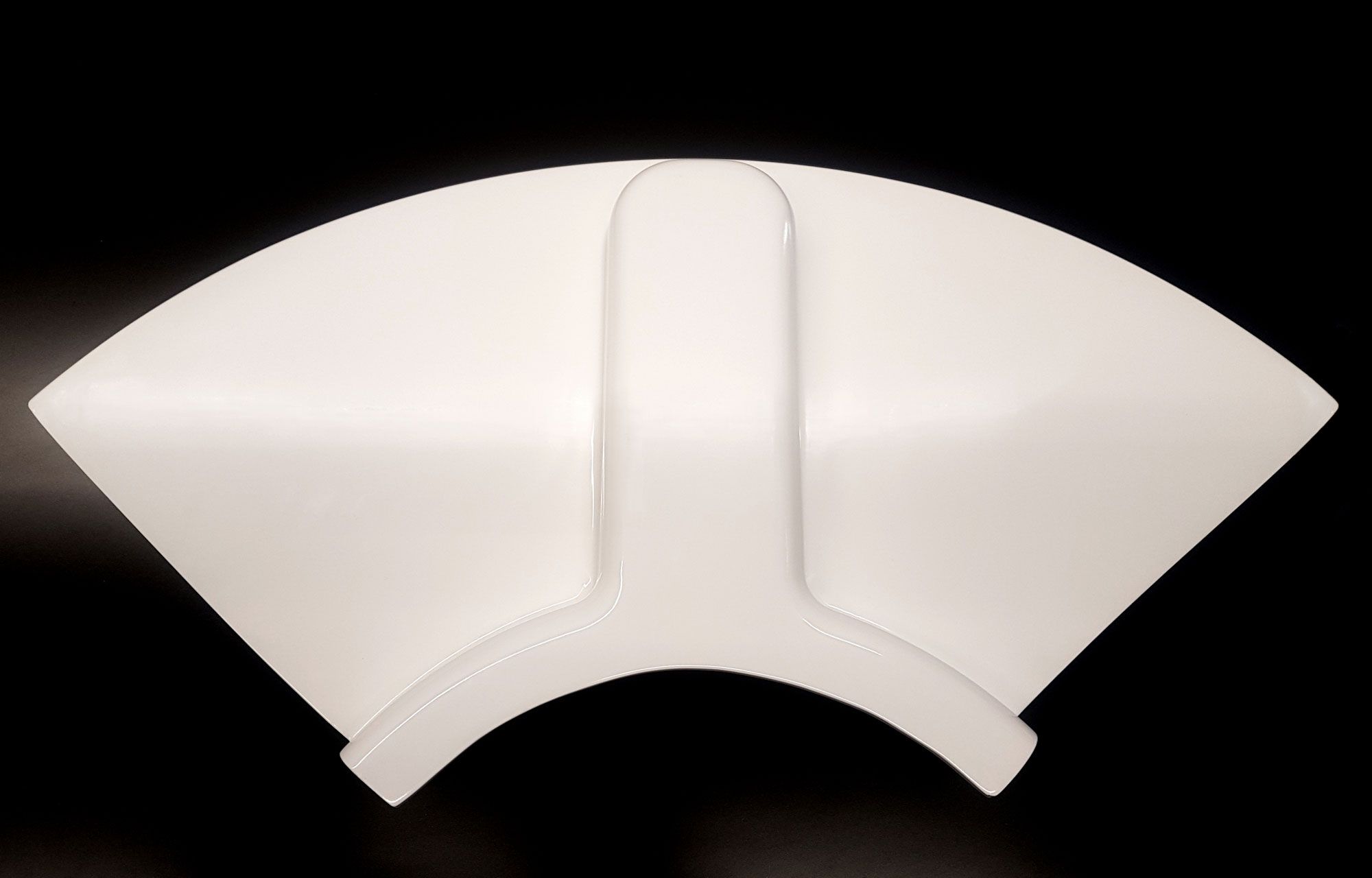

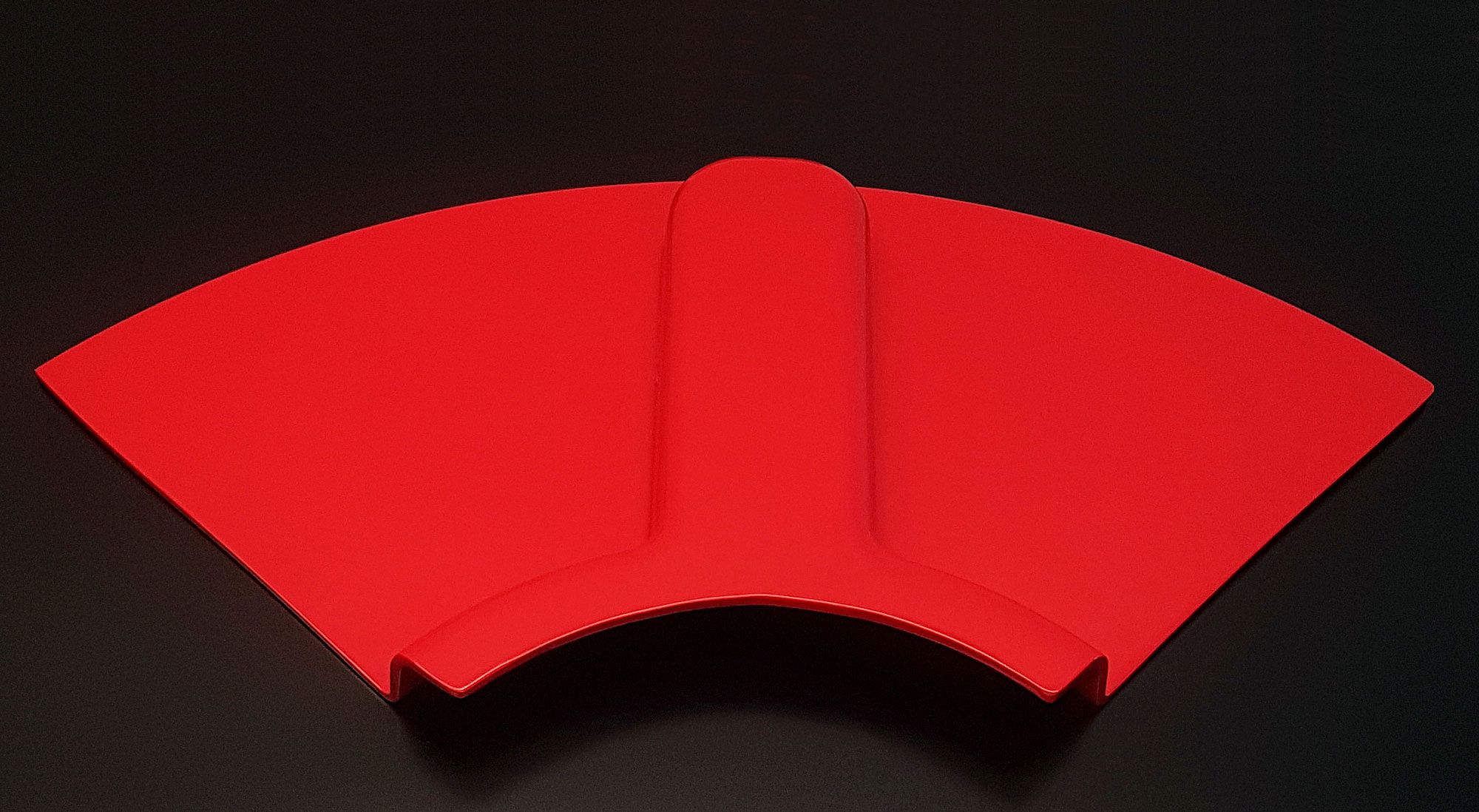

RTM - RESIN TRANSFER MOULDING

The RTM process includes hand lay-up of Glass Fiber into the mold. Then, the mold is closed and placed under a low vacuum System so that the resin can uniformly permeate the fiber when injected. The mold remains closed until the resin is cured.

As the curing is over the mould is open and the product removed.

The RTM pieces can be considered finished both sides but for an upgrade of the surface we can Spray Gelcoat or Paint. By RTM we are able to produce very resistant and hi end Products, in the view of low Series of Production. It's an alternative to the Rigid Polyurethane.