PORCELAIN

It is considered the higher espression of the ceramic materials. Main component of porcelain is a particular white clay: the kaolin (Aluminium Idrossisilicate). Was invented in China around the VIII century; other components of the porcelain are the silicium quartz sand and the feldspar.

Kaolin provides the white color and the plastic properties; quartz the possibility of glazing, feldspar allows the melting of all the components. Firing is done at 1280° around.

Many types of porcelain do exist worldwide, according to the various heritages and production areas.

Glazing and second firing of the porcelain

The glazing (transparent or coloured) is mainly to create in the finish product the effects of waterproofing, to provide thermal insulating and make easier cleaning/washing. Generally the glaze used for porcelain is lead free and a second firing is operating after glazing, at 1500°.

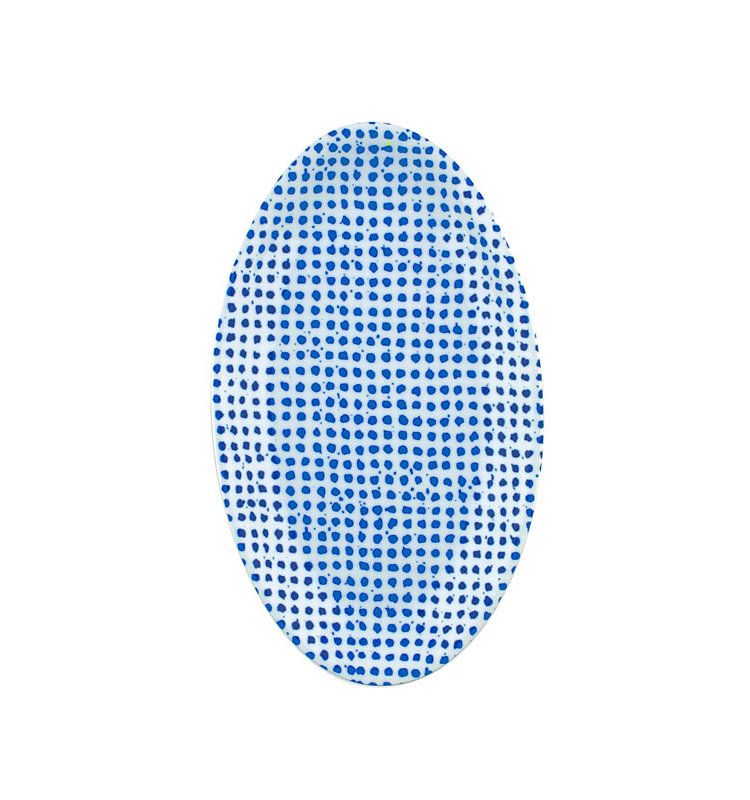

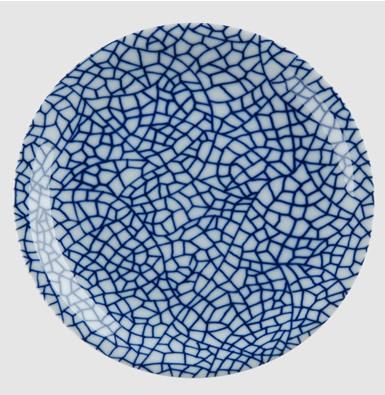

Our makers are based in Far east, specialized in the tableware, developing the customized Design on total exclusive bases.