POLYURETHANE AND SEATS

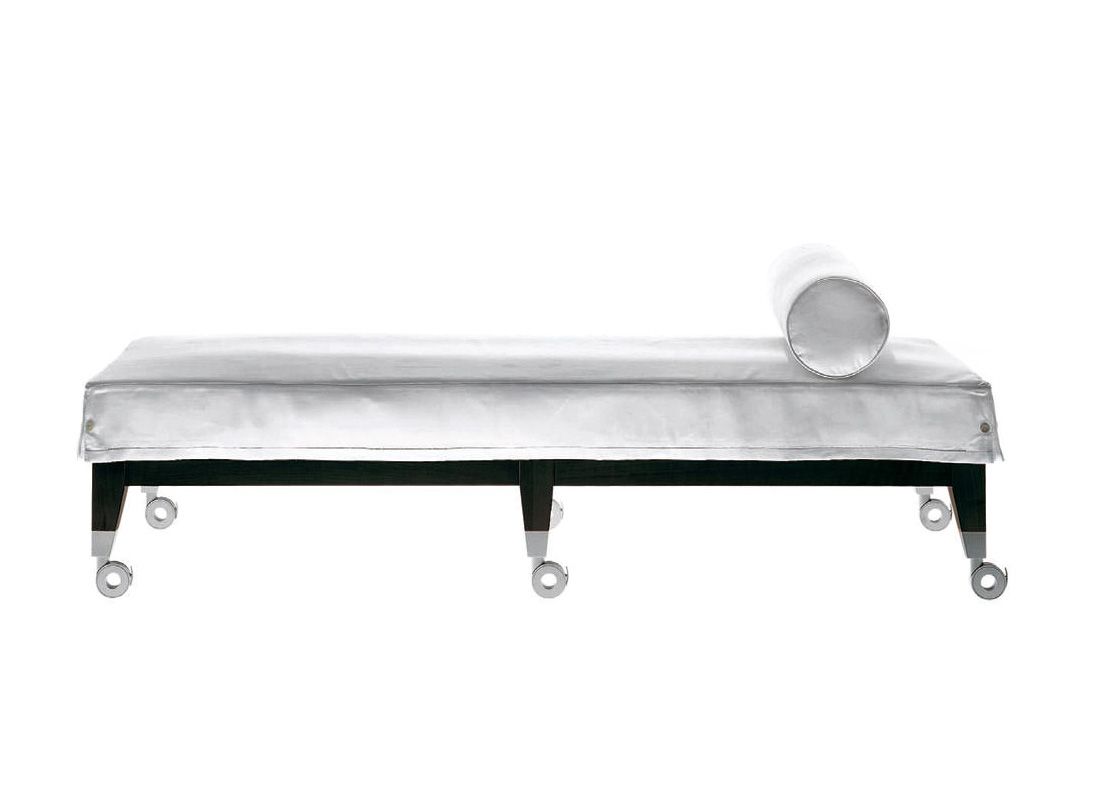

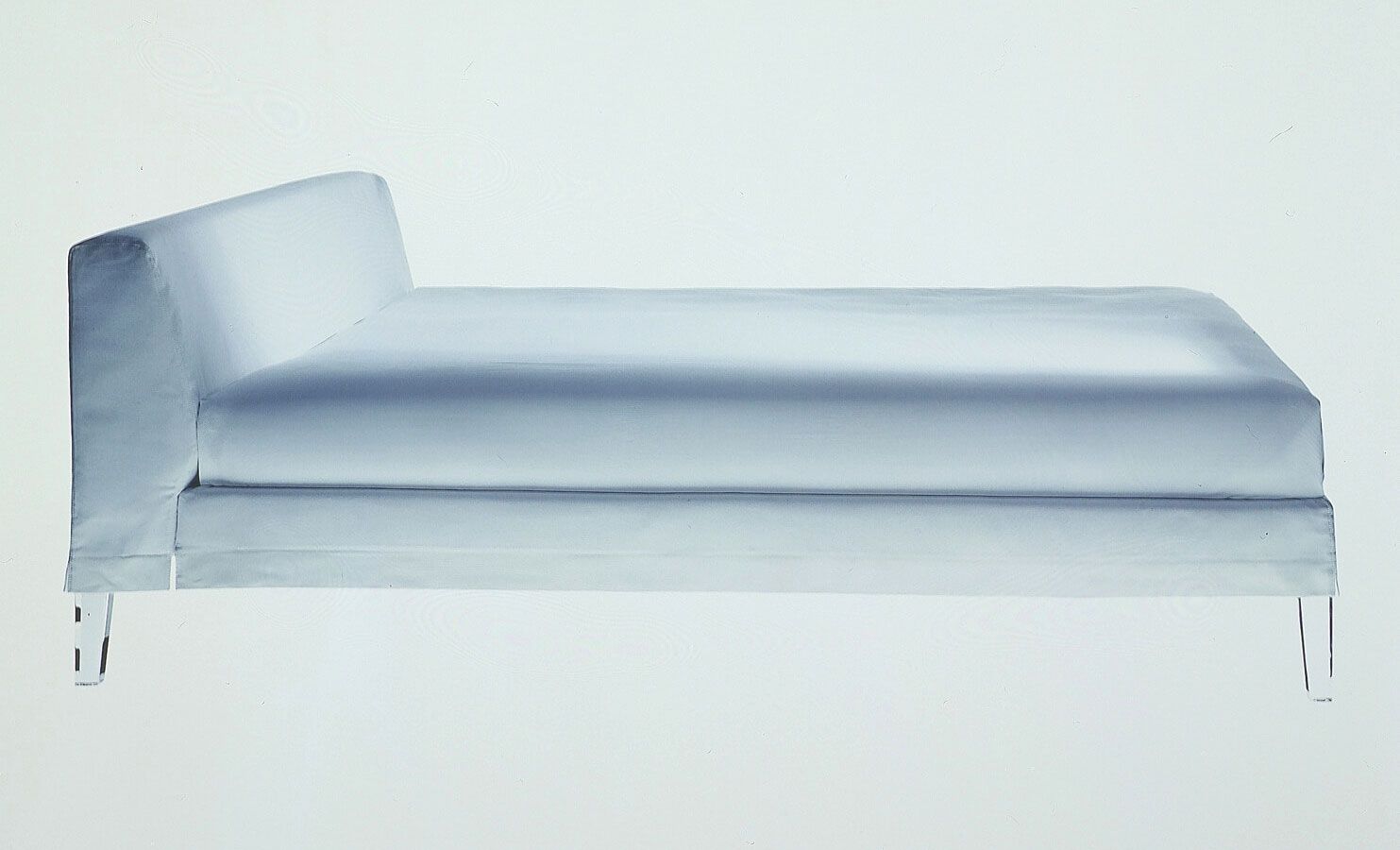

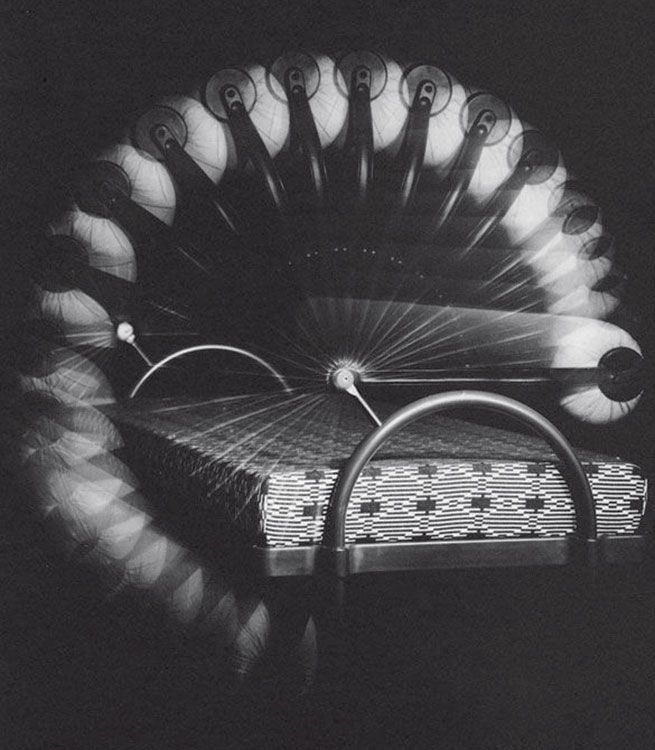

The Polyurethane is the basic component in manufacturing the Upholstered Furniture. It can be processed by cutting from the ready made "Blocks" rather than "Foamed" at low temperature and pressure by pooring the liquid mix into a mould. Then the forms are glued to a self resistant structure (wooden or metal made) and then again the forms are wrapped (white cover) by natural or synthetic covers prior to "wear" the very final cover in Textile or Leather.

The Top level upholstered items do have certain plus who are distinctive along the life of the product: the safe framing and belt system using massive wood or steel, different densities of Hi Resilience Pu foam, pure polyester fibers, the particolar care to the seat or back cushions by using special fibers or goose feather, attention in the details and stitchings, quality of leather or fabrics.

Lately many foreign markets for home and all the most important for contract started with restrictive inquiries in term of fire resistance regulations. Now we can say that all the most important producers of Pu, fibers and fabrics have a wide range meeting the more restrictive regulations as the British Standard or Italian Classe 1IM.

The last important remark is for the recent raising of know how and quality for the Outdoor Cushions manufaturing, not just for the filling–padding materials but also for te Textile and Leather covers.